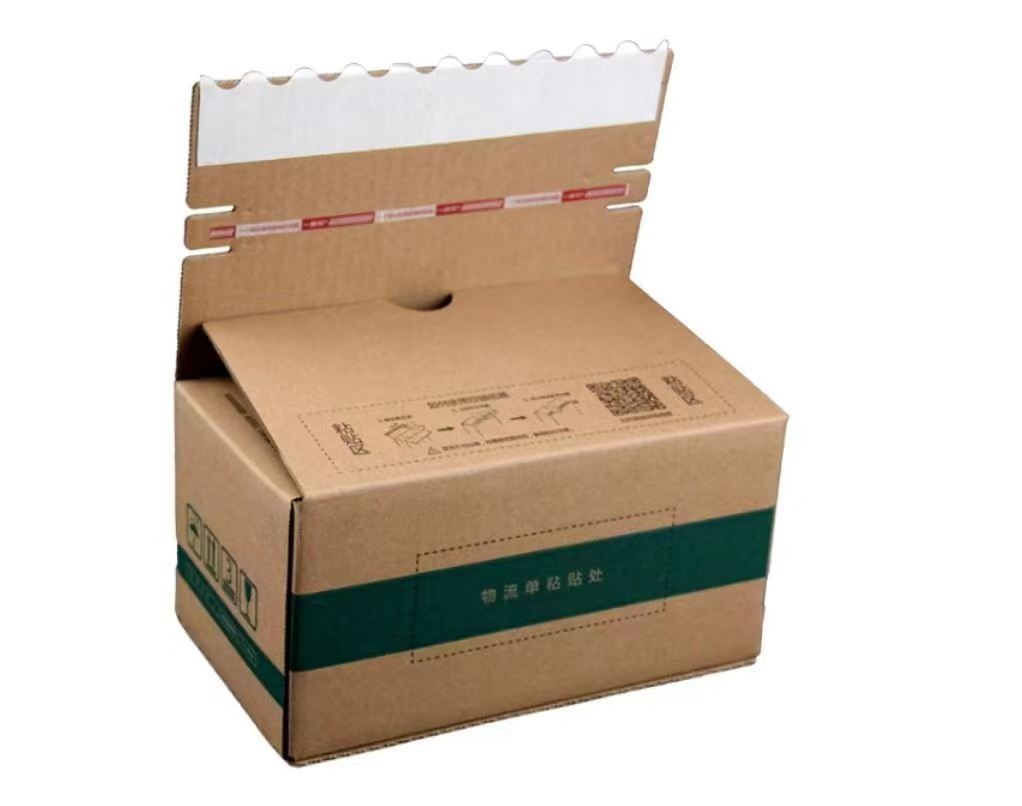

Nws pib ob daim kab xev daim ntawv thov Tshuab

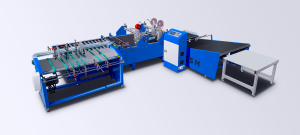

Cov ncauj lus kom ntxaws ntawm CS - 1800 tsis siv neeg ob-sided nplaum sib txuas tshuab

| Khoom siv: | Ntau tshaj 300 g / m² Cardboard E -, B -, peb txheej thiab tsib txheej corrugated ntawv |

| Qhib qhov khoob: | min.250 x 250 mm |

| Max.1800 x 1800 mm | |

| Ua haujlwm dav: | 1800 hli |

| Conveyor ceev: | 70 m / min (qhov ceev ceev yog nyob ntawm cov ntaub ntawv thiab lub thawv hom) |

| Daim kab xev yob dav: | Ib qho yooj yim tsim kua muag daim kab xev 4-8mm, ob-sided nplaum daim kab xev 5-40mm |

| Precision: | +/- 2mm (kev ua tau zoo sib txawv raws li ob-sided nplaum daim kab xev thiab lub thawv hom) |

| Sticking style: | Longitudinal gluing |

| Number of installable daim kab xev applicators: | 1 yooj yim tsim kua muag daim kab xev applicator, 2 txheej ntawm ob-sided nplaum applicators |

| Xav tau huab cua: | min.6 bar |

| Lub zog xav tau: | 8.5KW (380V AC 3φ 50HZ) |

| Qhov hnyav: | txog 3200KG |

| TshuabLoj: | 8200 * 2200 * 1250m (L * W * H) |

Main hluav taws xob Cheebtsam thiab hom

| xaj | npe | hom |

| 1 | Main Tsav | CHENGBANG |

| 2 | Calibration Tsav | CHENGBANG |

| 3 | Feeder Tsav | CHENGBANG |

| 4 | Main Tsav zaus Inverter | PANASONIC |

| 5 | Calibration zaus Inverter | PANASONIC |

| 6 | Feeder zaus Inverter | PANASONIC |

| 7 | Tswj System | MITSUBISHI |

| 8 | Photoelectric Sensor | TSEEM CEEB |

| 9 | Main Tsav Bearing | NWS, SKF |

| 10 | Electromagnetic contactor | SCHNEIDER |

| 11 | Applicator Lub electromagnetic valve | SMC |

| 12 | Lub tog raj kheej | SMC |

| 13 | Kev nyab xeeb relay | SCHNEIDER |

| 14 | Contactor | SCHNEIDER |

sau tseg: Cov khoom saum toj no 14 yog qhov tseem ceeb

Kev Taw Qhia Kom ntxaws

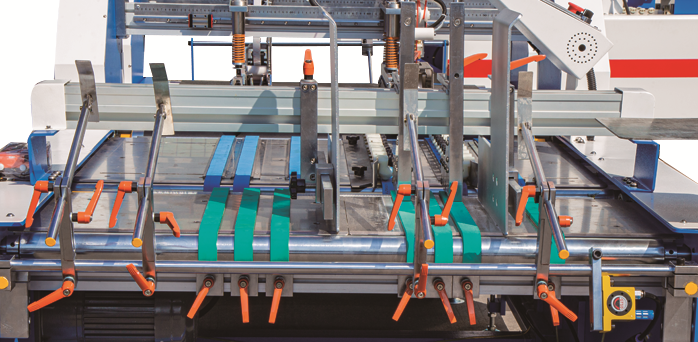

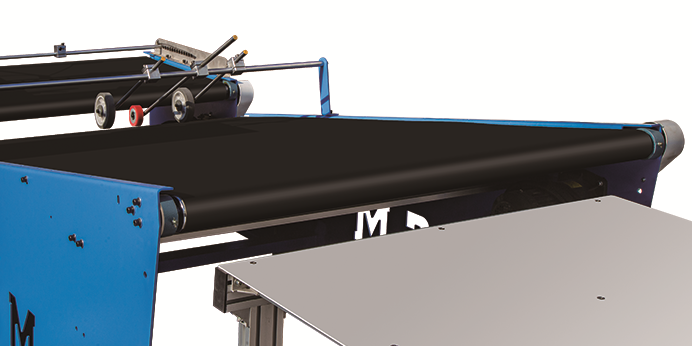

| Conveyor Section | |

| Nws siv cov qauv sau cov qauv tsim thiab 2 hli thickness siv (ntshuam) yog mos txaus los tiv thaiv cov khoom los ntawm nias puas, thiab xyuas kom meej lawv zoo meej

|  |

Sau koj cov lus ntawm no thiab xa tuaj rau peb